Solidworkds Drawing Datrum Feature on Plane

A frequent question almost 3D annotations is how a datum symbol tin exist attached to a centerline, an axis or a center plane of solid bodies. This SOLIDWORKS MBD forum post provides a recent case. Datum features are the foundation of composing and interpreting geometric dimensioning and tolerancing(GD&T) definitions. When we locate a physical address on a map, we reference the country, state, city and street of the address. Datum features provide similar references in a characteristic control frame. So allow'due south look into this important topic in this article.

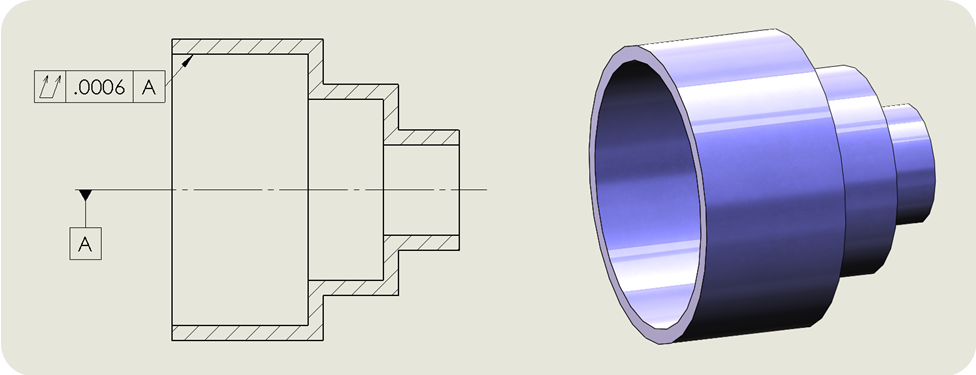

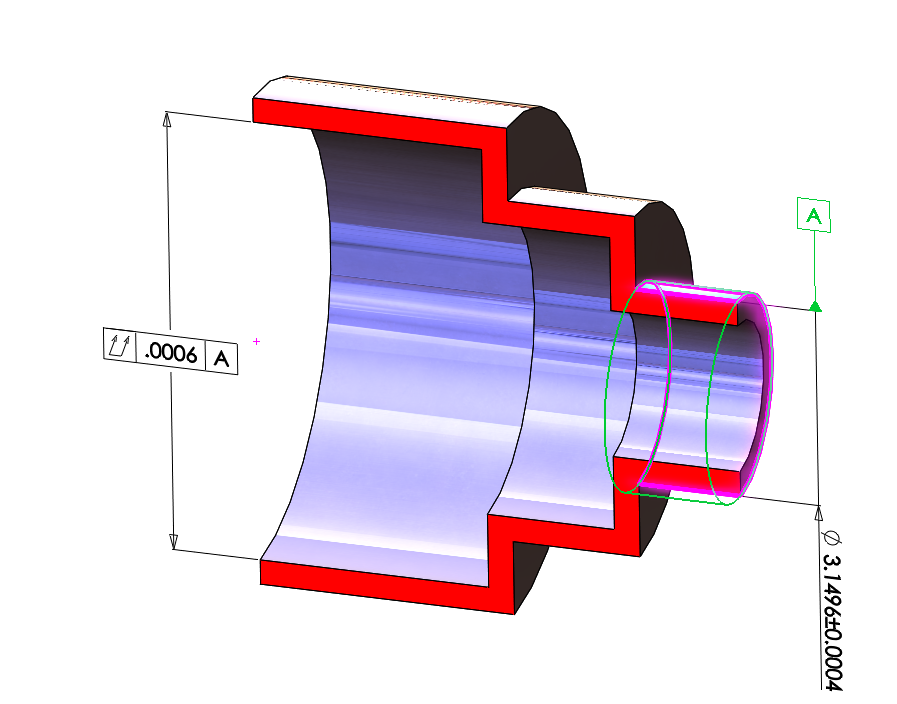

We tin can brainstorm by asking the question: Practise you encounter any trouble with the GD&T definition in Figure ane? In the figure, datum symbol A is fastened to a centerline and then is referenced in a total runout tolerance.

Figure one. A problematic GD&T definition. (Epitome courtesy of a Tec-Ease GD&T tip video.)

Figure one. A problematic GD&T definition. (Epitome courtesy of a Tec-Ease GD&T tip video.)

This really turned out to be a meg-dollar problem. The original part by a customer was a lens barrel in a space telescope on which the opening at the left interfaced with a lens, which is why the total runout tolerance was controlled tightly at 0.0006 inch. Figure one is a simplified illustration of the function.

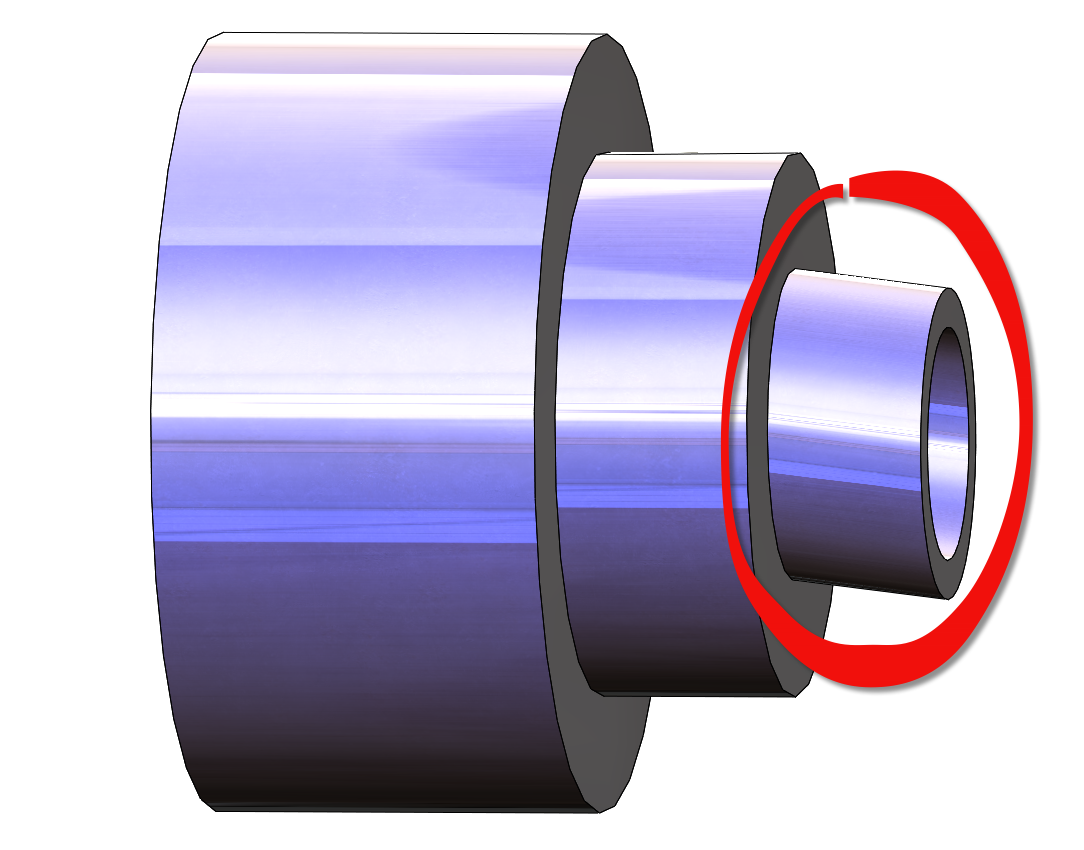

A tight tolerance is fine every bit long equally the product function justifies information technology. The real problem with this part is the datum characterization attached to the centerline on the client drawing, because it didn't specify which tangible feature would serve as the datum feature to inspect the tight tolerance. A centerline is theoretical and intangible. In the actual product, the supplier inspector didn't have definitive instructions on how to hold the function. Effigy 2 shows an exaggerated instance of a machined part by the supplier. Clearly, the smaller cylinder on the correct of the figure was misaligned.

Figure 2. An exaggerated case of a machined role.

Figure 2. An exaggerated case of a machined role.

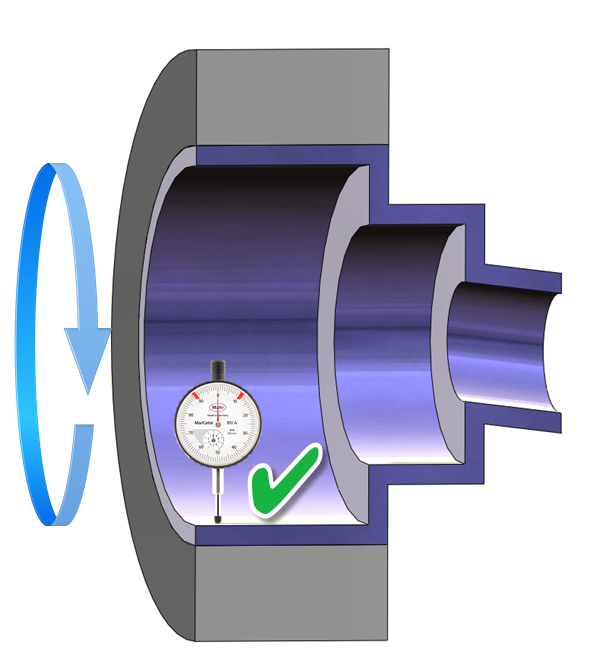

If the supplier grabs a convenient feature such as the larger outer cylinder on the left, spins the part, and so inspects the runout, the function is skilful as what is shown in Figure three.

Figure 3. Inspecting the total runout by property the convenient larger outer cylinder.

Figure 3. Inspecting the total runout by property the convenient larger outer cylinder.

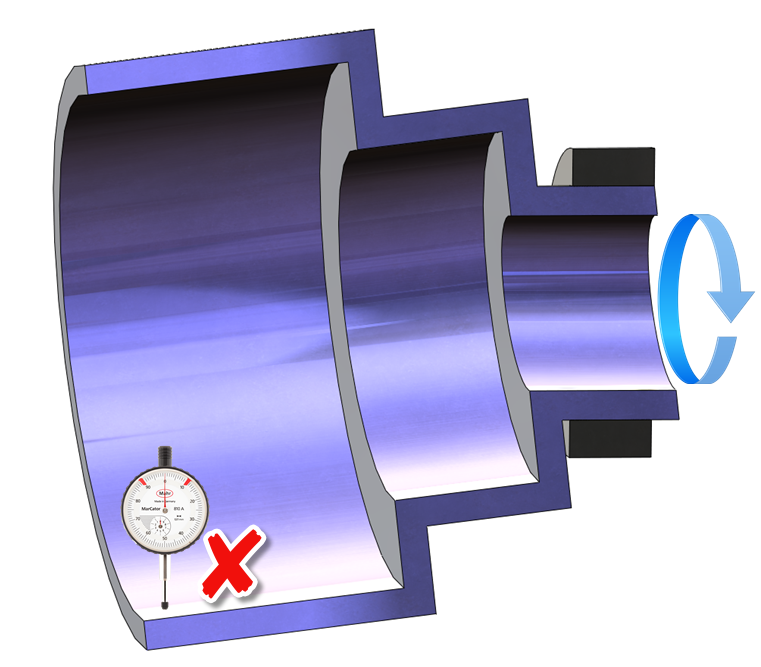

Unfortunately, the customer held the barrel in the fashion it would assemble in the lens mount. As a issue, the smaller cylinder on the correct should be spun to inspect the function based on the intent of the design. Now, equally shown in Effigy 4, the total runout is violated and the function should be rejected. This ambiguity led to a lawsuit of about$8 million.

Figure 4. Inspecting the total runout by holding the smaller outer cylinder.

Figure 4. Inspecting the total runout by holding the smaller outer cylinder.

This trouble could have been easily avoided if the symbol was specifically defined to an intended tangible feature, rather than an ambiguous geometry. Figure 5 shows the recommended definition using SOLIDWORKS MBD. In this approach, you can select the smaller outer cylinder to ascertain the feature. The software and so highlights the actual face once a characterization is selected and automatically aligns the datum symbol to the size diameter and tolerance callout.

Figure v. A recommended datum characteristic definition.

Figure v. A recommended datum characteristic definition.

This lens butt example demonstrates the costly downside of ambiguous GD&T definitions. Although this issue tin occur in both 2D drawings and 3D annotations, some MBD software guides the definitions with born GD&T rules to ensure solid practices. For example, Johnson Controls estimated significant value benefits with improved GD&T practices in the CATIA MBD environment.

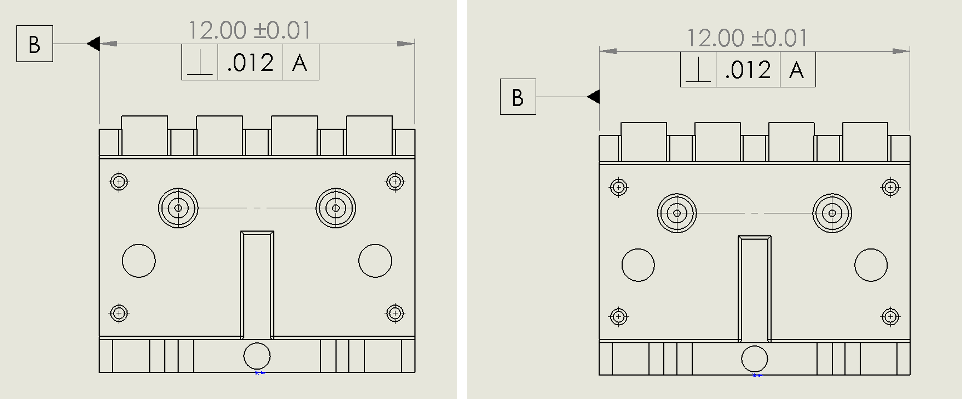

Similarly, SOLIDWORKS MBD follows the ASME Y14.v-2009 GD&T standard closely. For instance, according to this standard, the datum feature symbol B in the ii figures when compared to Figure 6 conveys two completely different design requirements. The 1 shown on the left indicates that datum feature B is the width feature because the characterization B is aligned with the width dimension line, while the i shown on the correct indicates that datum feature B is only a unmarried face up considering the characterization is not aligned with the width callout.

Figure 6. A drawing comparing between a width characteristic as a datum characteristic (left) and a unmarried face as a datum feature (right).

Figure 6. A drawing comparing between a width characteristic as a datum characteristic (left) and a unmarried face as a datum feature (right).

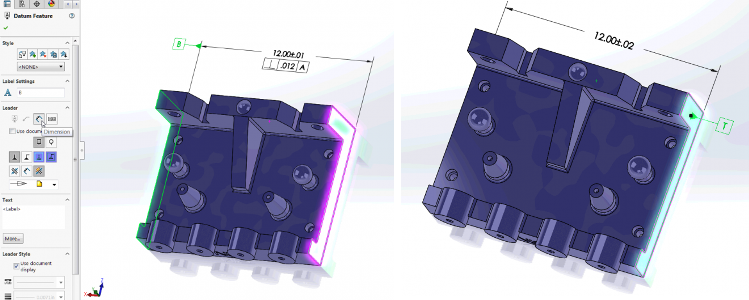

In club to avoid this common confusion, SOLIDWORKS MBD automatically aligns the characterization to the width characteristic size dimension line as shown on the left of Effigy 7. If the design requires just a face equally the datum feature, and then you tin define a face, rather than a width.

Figure vii. An MBD comparison between a width as a datum feature (left) and a single face every bit a datum feature (right).

Figure vii. An MBD comparison between a width as a datum feature (left) and a single face every bit a datum feature (right).

By the way, a width datum characteristic gives the eye aeroplane between the two opposing faces every bit the theoretical datum. I promise this answers the frequent question posed at the beginning of this commodity. You can discover more about the differences between datum feature and datum here.

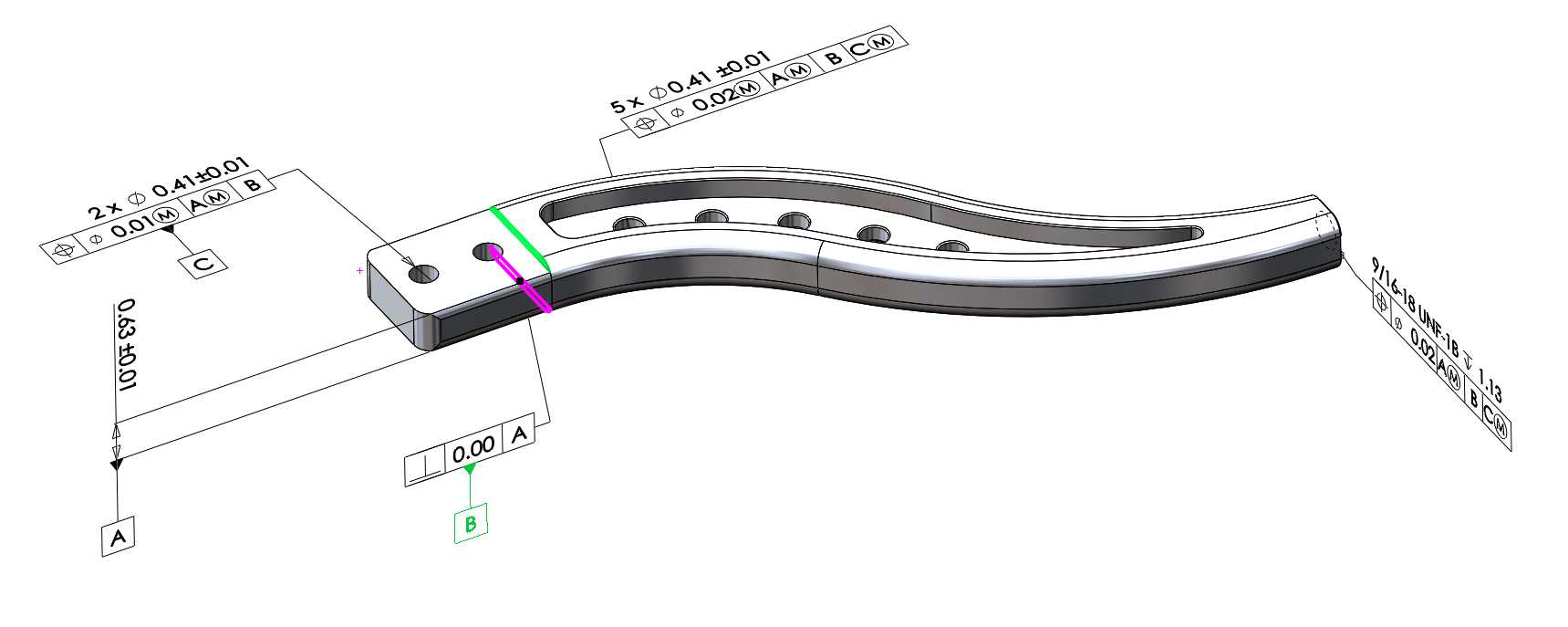

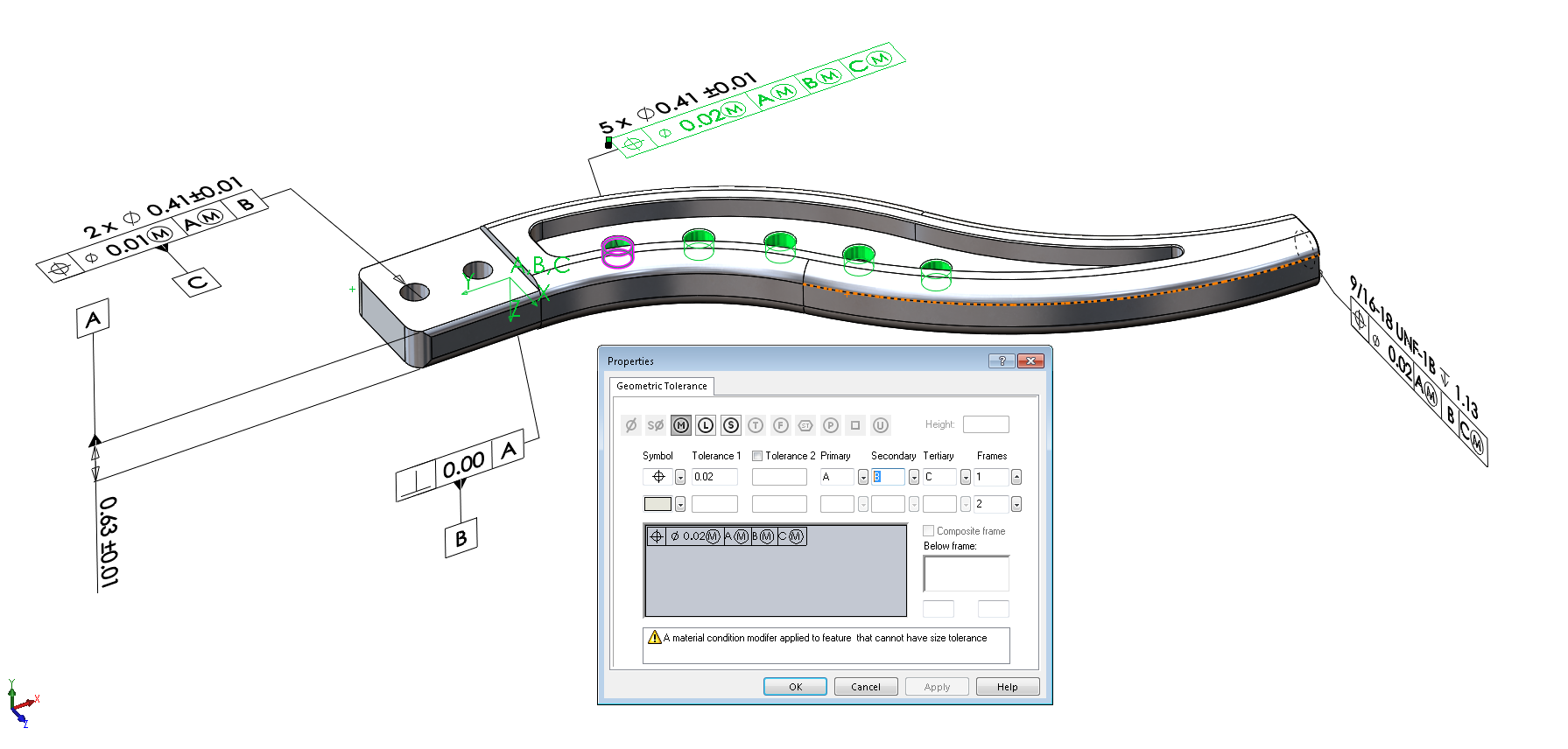

Allow'south expand to several other examples. Figure eight shows the datum features A, B and C on a shifter stick. A is the width size feature, B is the two coplanar shoulders every bit highlighted in green, and C is the blueprint of two mounting holes that is supported past a new enhancement in SOLIDWORKSM MBD 2018.

Figure 8. Datum features A, B and C on a shifter stick.

Figure 8. Datum features A, B and C on a shifter stick.

In this ABC datum framework, I added the Maximum Cloth Boundary (MMB) modifiers to A and C, which are size features. This allows datum shifts to accept more than good parts. Even so, if I were to add MMB to datum feature B as shown in Figure 9, the software would flag it because B is not a feature of size and maximum fabric purlieus doesn't apply in this case.

Figure 9. A alert message confronting using an incorrect MMB modifier.

Figure 9. A alert message confronting using an incorrect MMB modifier.

You may also observe that when a feature control frame is selected, the coordinate system as defined by the ABC datum references is automatically created and highlighted in green in the graphics surface area. This provides an instant visual confirmation that makes interpretation easier. It also helps automate the coordinate organisation alignment for other downstream manufacturing software.

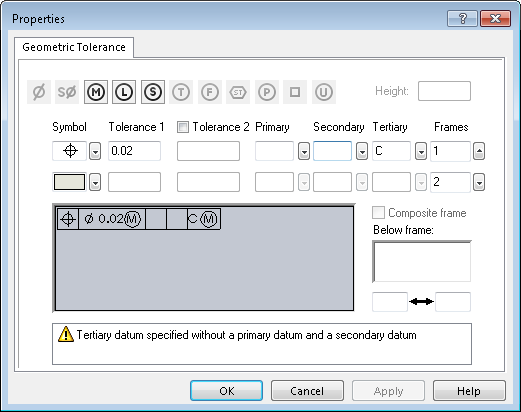

On this GD&T editing dialog, if a user forgets to type in a primary or secondary datum alphabetic character before a tertiary ane in a feature control frame, the dialog automatically displays a warning message to alert the user as shown in Figure 10.

Effigy x. A warning message virtually missing principal or secondary datum letters.

Effigy x. A warning message virtually missing principal or secondary datum letters.

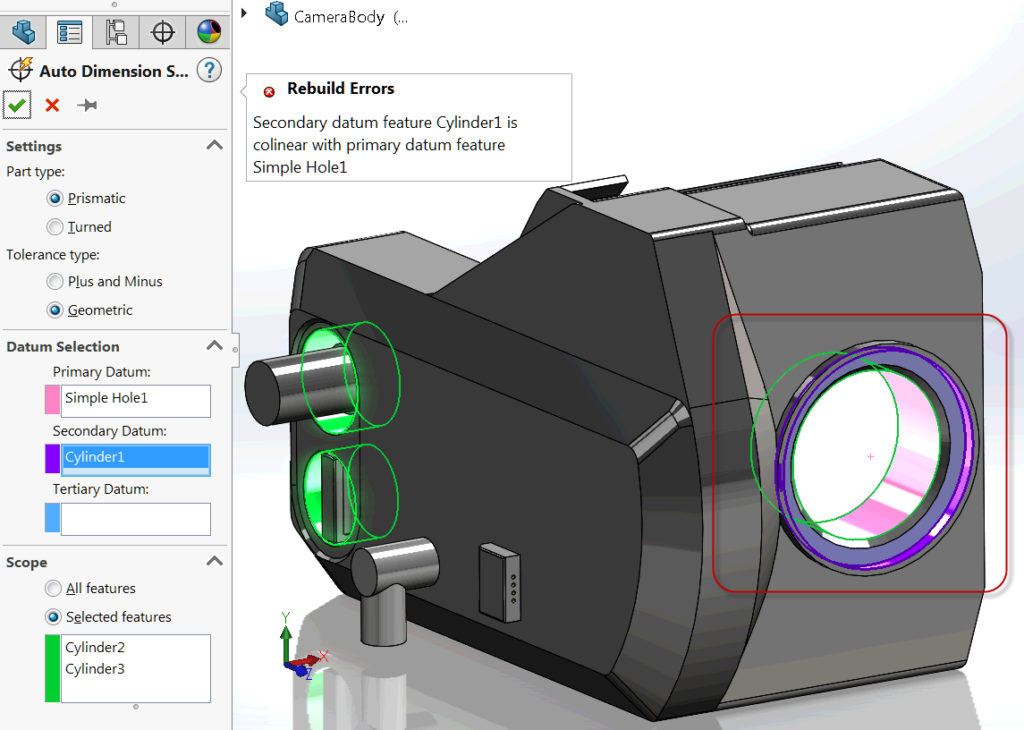

Besides the manual annotations, the software follows the GD&T rules in the automatic dimension cosmos also. Figure 11 illustrates an error in which the 2 datum features in the red box share the same axis. The features are defining the same theoretical datum, so the tool catches their unnecessary duplication.

Figure xi. An unnecessary datum feature duplication caught in the automated dimension scheme.

Figure xi. An unnecessary datum feature duplication caught in the automated dimension scheme.

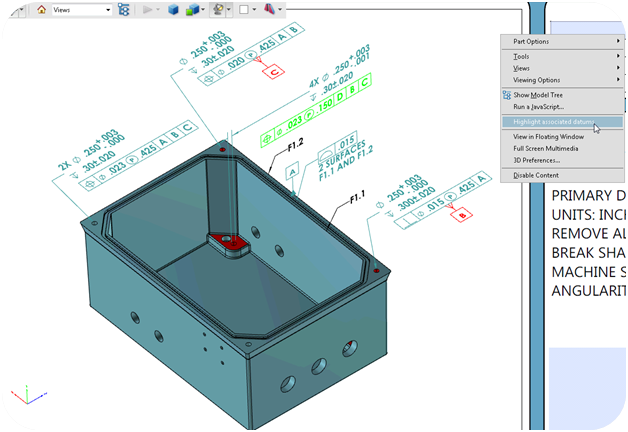

As mentioned at the beginning of this post, when interpreting a GD&T definition, a user showtime needs to remember the datum references. So, a handy command is to automatically highlight the associated datum symbols and features. The 3D PDF generated by SOLIDWORKS MBD provides this control shown in Effigy 12. You tin correct-click on a characteristic control frame and click on the context carte du jour command "Highlight associated datums." I hope that a similar handy capability can be added to the SOLIDWORKS surroundings in the time to come.

Figure 12. Highlight associated datum symbols and features for a characteristic control frame.

Figure 12. Highlight associated datum symbols and features for a characteristic control frame.

With that, allow's conclude this article with several key points:

- Datum features are the foundation of GD&T definitions.

- You should define datum features on tangible faces, rather than intangible ambiguous geometries.

- SOLIDWORKS MBD builds GD&T rules into the software to help notice violations.

If you lot have any comments or questions, please feel gratis to get out them in the comments area beneath. To learn more than nearly how SOLIDWORKS MBD can help implement your Model-Based Enterprises, delight visit its product folio.

About the Writer

Oboe Wu is a SOLIDWORKS product manager with xx years of feel in engineering and software. He is an advocate of model-based enterprise and smart manufacturing.

Source: https://www.engineersrule.com/ensure-solid-gdt-datum-practices-solidworks-mbd/

0 Response to "Solidworkds Drawing Datrum Feature on Plane"

Enregistrer un commentaire